The dawn of 2024 brings with it more than just another year—it represents a bold stride into an era of unprecedented technological innovation in construction. Let’s delve deep into three transformative trends: Building Information Modeling (BIM), Construction Robotics, and 3D Printing.

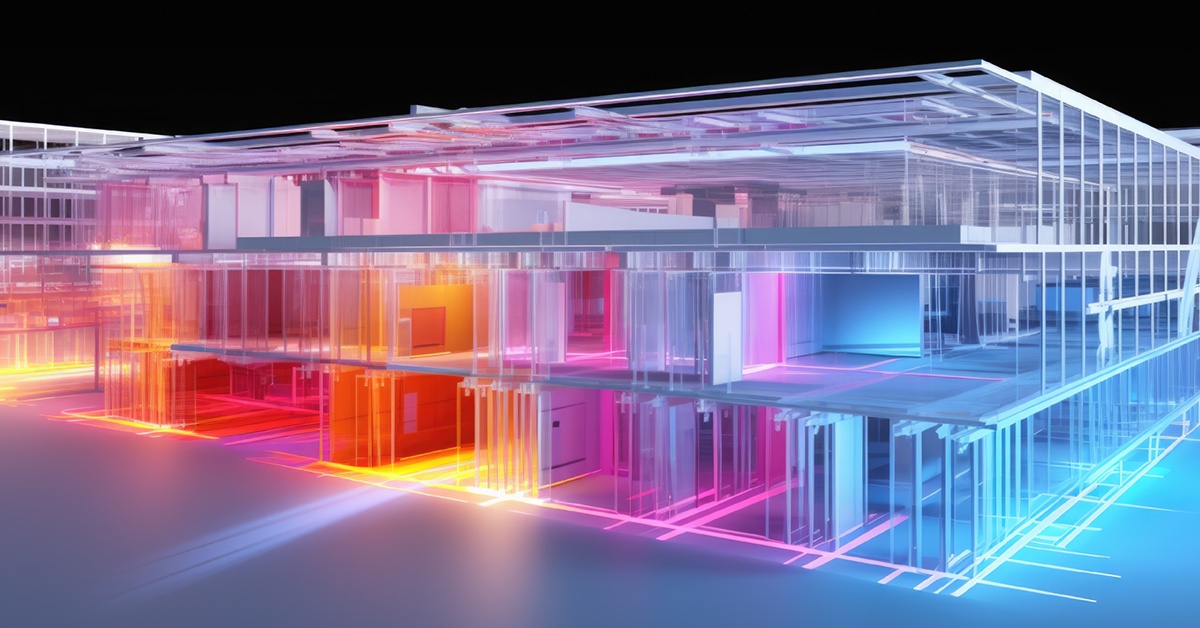

BIM: A Whole New Way to Collaborate and Visualize

Building Information Modeling, commonly known as BIM, isn’t just another tech jargon—it’s fundamentally changing the way projects are conceived and executed. No longer confined to the tedious interpretation of 2D blueprints, industry professionals can now visualize, analyze, and optimize their projects like never before.

Industries on the BIM Frontline & Their Upgrades:

Post-construction, BIM continues to serve as an invaluable asset for facility management, offering insights into building lifespan, maintenance schedules, and energy consumption patterns. As green building standards become increasingly important, BIM’s role in sustainable construction is expected to grow even further.

Construction Robots: Building Faster, Safer, and Smarter

The concept of robots in construction was once a topic for futuristic fiction. Today, it’s a rapidly unfolding reality. These machines are bringing unmatched precision, scalability, and safety to construction sites, transforming traditional practices.

Industries Embracing Robotic Helpers & Their Enhancements:

The integration of AI and machine learning in construction robotics promises further advancements. By analyzing vast datasets, robots will increasingly predict and navigate site challenges, optimize material use, and even coordinate tasks with human workers, redefining collaboration on the construction site.

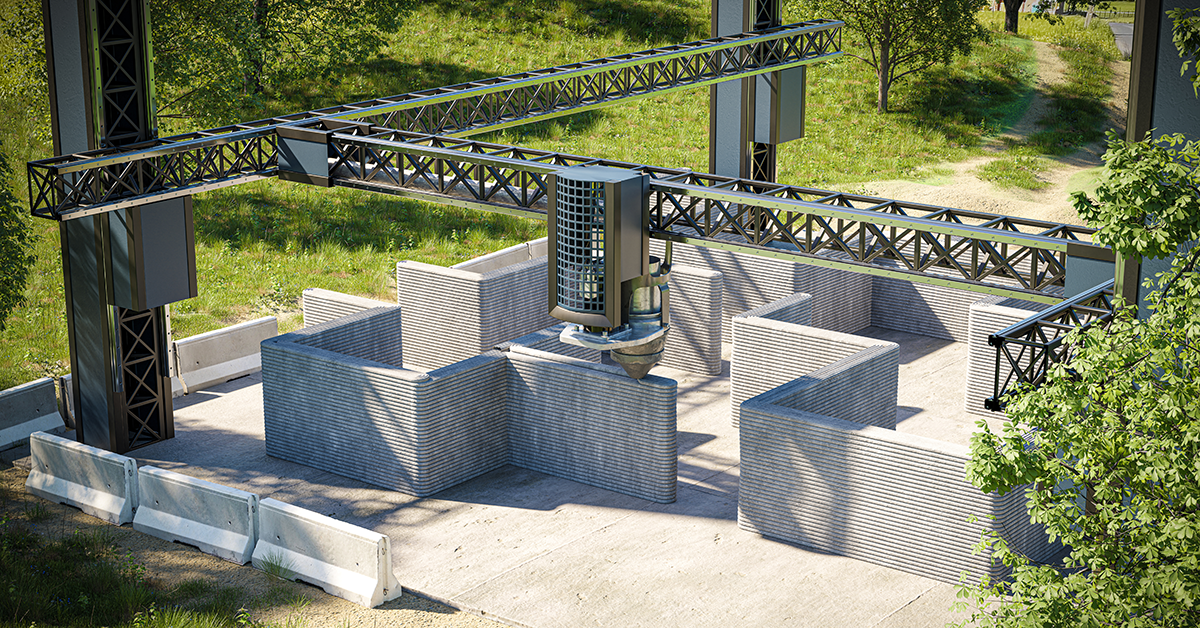

3D Printing: Layering the Future

3D printing, once restricted to prototype design in product manufacturing, is now venturing into the vast domain of construction. This technology is not just facilitating rapid construction but also championing design innovations that were previously deemed unfeasible or too costly.

Industries Sculpting Success with 3D Printing:

The next frontier for 3D printing in construction could be the use of advanced materials, allowing for properties like self-healing concrete or adaptable facades that respond to environmental conditions. As research continues, we’re likely to see even more radical innovations birthed from the synergy of 3D printing and construction.

Final Thoughts

The confluence of BIM, Construction Robotics, and 3D Printing is not merely introducing incremental changes—it’s revolutionizing the very foundation of the construction industry. For players in this dynamic field, embracing these innovations isn’t a mere option; it’s essential to driving growth, optimizing efficiency, and spearheading the future of construction.

STAY UP-TO-DATE!

Subscribe to receive our newsletters with insights and tips from industry experts.

RECENT ARTICLES

The Ultimate Guide to Finding Large Commercial Construction Project Leads (2025 Edition)

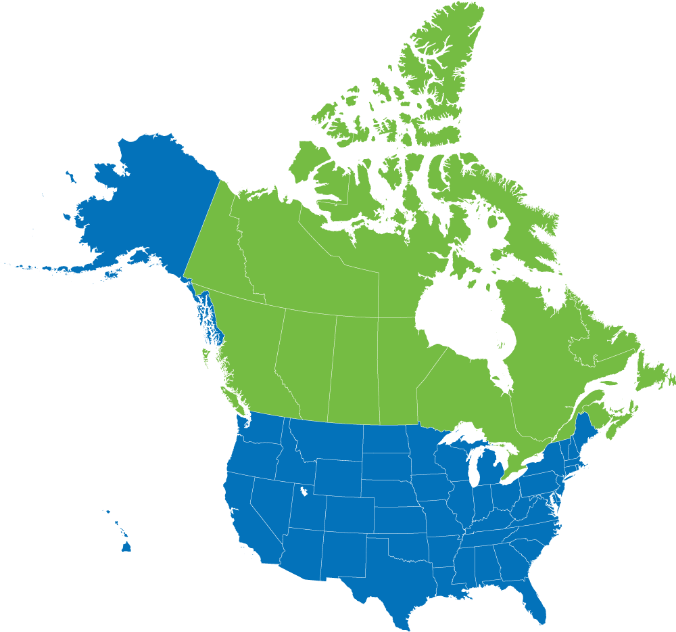

This 2025 guide breaks down the most effective strategies, tools, and platforms for finding commercial construction project leads. Whether you’re looking to diversify your project portfolio, expand into new regions, or scale your operations, this resource is your starting point.

Why Use a Construction Lead Generation Service? (Benefits for Large-Scale Projects)

If you're a contractor, supplier, or service provider looking to land more large-scale commercial jobs, chances are you've tried everything—referrals, bid portals, cold calls, and even LinkedIn messages. While those tactics still hold some value, they’re no longer enough to compete at scale.

Optimizing Your Online Presence to Attract Commercial Construction Leads

Whether you're a general contractor, subcontractor, supplier, or service provider, your online presence plays a critical role in attracting large commercial construction leads.